Is Exporting Hazardous Waste Safe?

Yes, exporting hazardous waste is safe as long as you work with a reputable and licensed transporter or treatment facility.

3 min read

Larry Burton

:

Nov 14, 2024 11:51:29 AM

Larry Burton

:

Nov 14, 2024 11:51:29 AM

If your company generates hazardous waste and ships that waste to a facility in the United States, you’re no stranger to the biennial report—it rolls around every two years like clockwork, bringing with it the need to account for every ounce of hazardous material you’ve handled.

Once hazardous waste is exported from the United States, it is no longer under the jurisdiction of the California Department of Toxic Services Control (DTSC) or the agency in the state where your business is located. It falls under federal regulation through the U.S. Environmental Protection Agency (EPA).

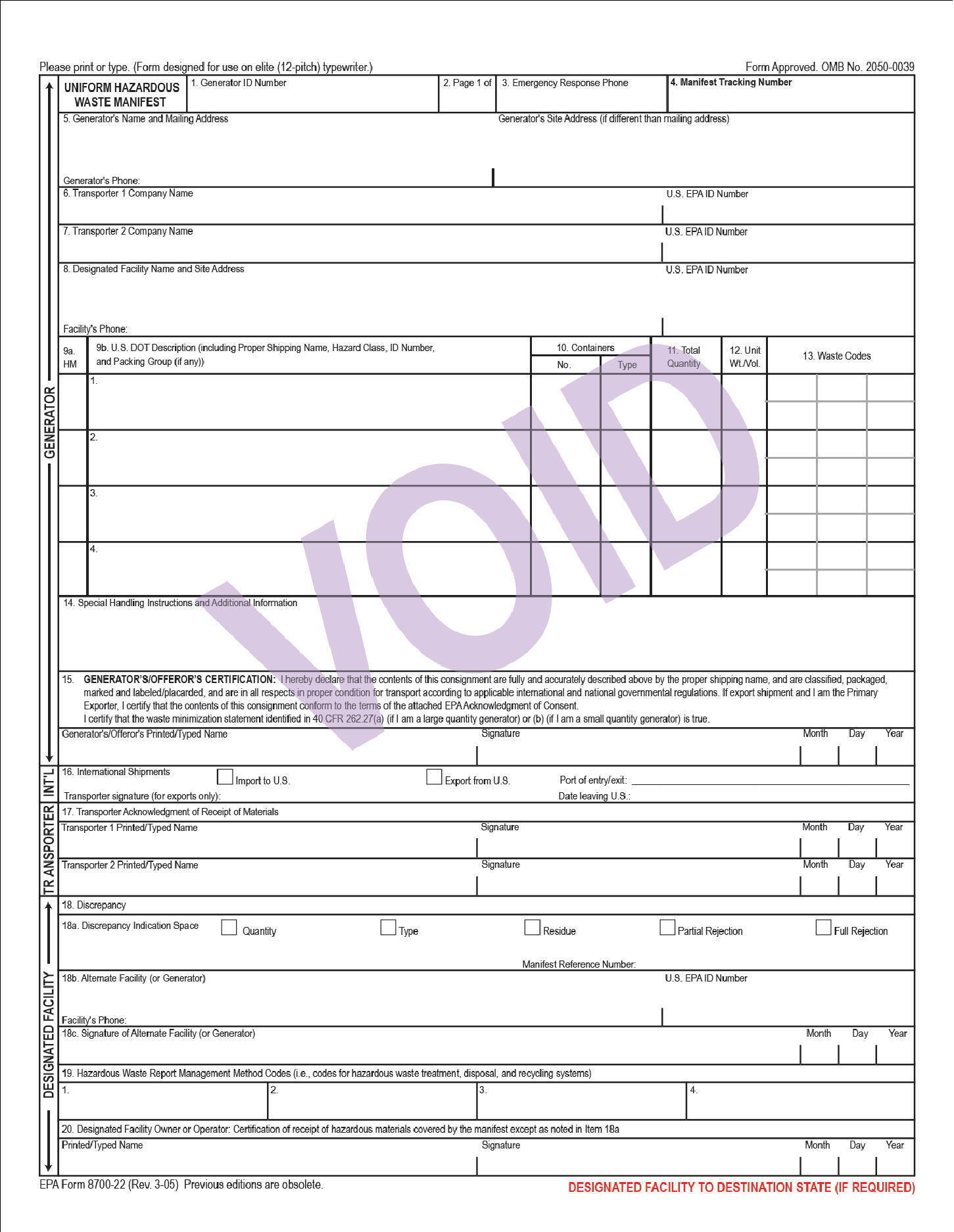

You’re also likely extremely familiar with the e-Manifest system, a digital platform that tracks hazardous waste shipments from cradle to grave, ensuring compliance and transparency at every step.

This year, the EPA began finalizing certain amendments to hazardous waste manifest regulations, including e-Manifest changes for transboundary shipments that clarifies the primary exporter and how biennial reporting will be integrated into the e-manifest system.

With these updates on the horizon, it’s more important than ever to stay informed about how the changes could impact your reporting and compliance responsibilities moving forward.

Biennial reporting is a regulatory requirement for companies that generate hazardous waste, as mandated by the EPA under the Resource Conservation and Recovery Act (RCRA).

under the Resource Conservation and Recovery Act (RCRA).

Every two years, hazardous waste generators must submit this detailed report outlining hazardous waste activities. The report includes the types and amounts of hazardous waste generated, how it was handled, and where it was ultimately sent for treatment, storage or disposal.

This biennial process serves as a key component in ensuring transparency and regulatory oversight. It helps both the EPA and state agencies track hazardous waste management practices, identify trends, and ensure that hazardous materials are being disposed of safely and in compliance with federal regulations.

If you export your hazardous waste, it’s important to understand how EPA e-Manifest and biennial reporting laws impact transboundary shipments. One of the most common places to export waste is Mexico, especially for companies located in the Southwest United States.

Because international shipments are covered by federal regulations, you must look at Federal statutes (40 CFR 262.56). Federal statutes are clear that the primary exporter must send an annual report to the EPA that includes all waste that is exported by them. That report includes all of the generator, manifest and waste exported information.

Biennial reporting for the generator must follow the instructions in RCRA Subtitle C Reporting Instructions and Forms, Page 118, Foreign Site Identification Numbers. Once your hazardous waste crosses the border from U.S. soil to Mexican soil, the primary exporter on record is responsible for submitting the manifest details on what was exported.

Here’s an example of how this process works:

Samex Environmental Services has the authorizations needed for the export of hazardous waste to Mexico where recycling technologies are available at our facility in Tijuana. The U.S.-based Samex starts the process of notifying the EPA (called a notice of intent) that hazardous waste will be transported across the U.S.-Mexico border. Mexico-based Samex Recycling Technologies (SRT) initiates the application process for the approval of the transboundary movement, or importation, of hazardous waste.

The primary exporter is Samex Environmental, while Samex Recycling Technologies is the importer. SRT is responsible for sending the facility copy of the manifest back to the generator after it receives the waste.

Keep in mind that primary exporters of hazardous waste must file a separate Annual Report under 40 CFR 262.56. This report is submitted by the primary exporter of record who may or may not be the actual generator.

Yes, the filing of biennial reports is integrated with the e-Manifest system. When a generator files its biannual report, the company logs into its account, pulls the information from the e-Manifest database, and reviews it to ensure the information is correct.

If the shipment is transboundary, the manifest will not be in the e-Manifest database. That will change once the primary exporter is tasked with uploading all of the manifests into the e-Manifest system.

As the EPA finalizes amendments to hazardous waste manifest regulations, including updates for transboundary shipments, biennial reporting will become more interconnected with the e-Manifest system, reducing paperwork and improving data accuracy.

By aligning the biennial report submission process with the e-Manifest system, companies will be able to manage their hazardous waste tracking and reporting more efficiently, ensuring that all required information is captured and reported in one centralized system. This change is designed to simplify compliance and improve regulatory oversight.

However, while this rule goes into effect Jan. 22, 2025, transboundary shipments will not be required to adhere until Dec. 1, 2025. This delay in enforcement will give both companies and the government time to finalize details and modify their systems.

As regulations continue to evolve, it’s critical to partner with companies that stay ahead of these changes to ensure seamless compliance.

Whether you’re managing hazardous waste on-site or exporting it across borders, working with a waste management company and TSDF that understand the latest e-Manifest and biennial reporting requirements can help you avoid costly mistakes and ensure that every step of the process meets federal and international standards.

Staying proactive with compliance not only protects your business but also contributes to a safer and more transparent hazardous waste management system.

Yes, exporting hazardous waste is safe as long as you work with a reputable and licensed transporter or treatment facility.

In manufacturing, efficiency isn’t just about maximizing production. It’s also about minimizing waste.

Solvent distillation stands out as a key technique in reclaiming valuable solvents and minimizing environmental impact.