Solvent Distillation

Thanks to our state-of-the-art technology, facilities are not only able to dispose of their waste safely

but can utilize a more cost-effective and environmentally friendly method to process their spent solvents.

5-Star Reviews

Happy Customers

Cups of Coffee

Virtual High-Fives

What Is Solvent Distillation?

Purifying spent solvents by batch distillation is accomplished by putting the waste into the still. Heat is added to bring the solution to a boil. Only the constituents with a boiling point (BP) lower than the set point on the equipment will change into a vapor state. Constituents with a higher boiling point will remain in the bottom of the still (still bottoms). The solvent that has transitioned to the vapor phase comes in contact with refrigerated condensing coils that transform the vapor into a pure liquid solvent. The pure solvent is packaged and ready to go back to the industry for industrial uses.

For example, acetone boils at 132.8F, toluene boils at 231F, and isopropanol boils at 180F. If you have a blend of those three solvents and the recovery still has the max temperature set at 250F, only those three constituents will transform into a vapor state. Other constituents, such as Stoddard solvent, with a BP of 300F, oil with a BP of 800F, and solids, will become still bottoms.

When the maximum temperature of 250F is reached, the machine turns off, and the still bottoms are removed. The still bottoms go to the fuel blending area to be blended into an alternative fuel.

Everything is used; nothing is wasted.

Taking Recycling & Sustainability To The Next Level

Samex Environmental, however, offers a State-Of-The-Art system that treats waste and turns it into reusable products that are then sold back into the industry.

By ensuring nothing is wasted, companies can take their sustainability initiatives to the next level.

Types Of Solvents Suitable For Distillation

Samex will receive solvents such as, Thinner, Alcohols, Acetone, Methyl ethyl ketone, Ethyl Acetate, Halogenated with the following characteristics:

- Pumpable/Dispersible Sludge <10%

- ph 4-10

- Density (specific gravity) .7 - 0.95

- Water <5%

- Heat Value >5,000 BTU

- Halogenated Solvents including Methylene Chloride with >50% yield

Solvents with a boiling point of >250F are unsuitable for distillation recovery.

At Samex We Are Committed To Excellence In The Management Of Hazardous Waste In Harmony With The Environment And Human Health

Driving Sustainability

Providing our clients with a sustainable recycling process to meet their recycling goals for a greener future.

Recycling Responsibility

Our recycling services help serve corporate sustainable policies by embodying responsible resource management and environmental stewardship.

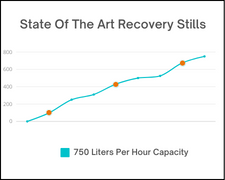

State-of-the-Art Equipment

Our State-of-the-art recycling equipment plays a pivotal role in safeguarding our environment by efficiently processing your waste materials.

Solvent Distillation

Partnering with Samex for your waste management needs not only ensures efficient solutions but also minimizes your company's long-term liability exposure.

Contact Samex

Solvent Distillation Recycling

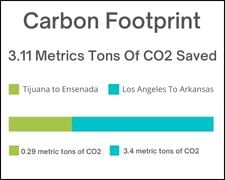

Carbon Footprint Emissions

From Tijuana to Ensenada, Mexico

Miles To Cement Kiln

Cargo Tons

Average truck emits 161.8 grams of CO2 per ton-mile

Total Metric Tons of CO2

The CO2 Emissions Savings Are Significant!

The average carbon emissions output for the same weight-based freight truck from Los Angeles to Benton Arkansas would be 3.4 metric tons of CO2.

Additional Sustainable Resources For Waste Recycling

How Does A Solvent Vapor Recovery System Work?

Larry Burton: Mar 31, 2025

True Or False: Flammable Liquids Are Those That Have A Flashpoint Of 590

Larry Burton: Mar 4, 2025

Feature Example

Asymmetrical butcher kickstarter enamel pin cold-pressed, woke grailed live-edge polaroid. Viral slow-carb stumptown, yr knausgaard health goth asymmetrical.

Feature Example

Asymmetrical butcher kickstarter enamel pin cold-pressed, woke grailed live-edge polaroid. Viral slow-carb stumptown, yr knausgaard health goth asymmetrical.

Feature Example

Asymmetrical butcher kickstarter enamel pin cold-pressed, woke grailed live-edge polaroid. Viral slow-carb stumptown, yr knausgaard health goth asymmetrical.

Feature Example

Asymmetrical butcher kickstarter enamel pin cold-pressed, woke grailed live-edge polaroid. Viral slow-carb stumptown, yr knausgaard health goth asymmetrical.

Let Us Know How We Can Help!

Click the button to launch a pop-up form to contact us.

Let Us Know How We Can Help You.

Complete the form below and one of our specialists will contact you.