E-Manifest System And Biennial Reporting Requirements

If your company generates hazardous waste and ships that waste to a facility in the United States, you’re no stranger to the biennial report—it rolls...

3 min read

Larry Burton

:

Jan 27, 2025 1:21:56 PM

Larry Burton

:

Jan 27, 2025 1:21:56 PM

In today’s manufacturing and industrial landscape, businesses are under increasing pressure to balance operational efficiency with environmental responsibility.

A well-designed sustainability plan is the key to achieving that balance.

From managing resources more effectively to minimizing waste and reducing carbon footprints, sustainability in project management requires a strategic approach at every stage. When drafting your sustainability plan in project management, here are some important considerations to include:

Efficient resource management is a vital aspect of sustainability in project management, particularly for manufacturing and industrial projects. By focusing on reducing raw material use, selecting eco-friendly materials and optimizing energy consumption, businesses can minimize environmental impact while also improving cost efficiency.

industrial projects. By focusing on reducing raw material use, selecting eco-friendly materials and optimizing energy consumption, businesses can minimize environmental impact while also improving cost efficiency.

One effective strategy for reducing raw material use is to optimize product designs, streamlining them to require fewer resources without sacrificing quality or functionality. Reusing and recycling materials also play a significant role. For instance, scrap materials or byproducts can be reintegrated into production processes, creating a closed-loop system.

When selecting materials, businesses should prioritize eco-friendly and sustainable options. Conducting life cycle assessments can help evaluate the environmental impact of materials from extraction through disposal, enabling informed choices that align with sustainability goals.

Energy consumption is another critical area for optimization. Conducting energy audits can identify inefficiencies in equipment, lighting and operations, providing a roadmap for upgrades like LED lighting or high-efficiency motors. Smart monitoring systems are invaluable for tracking real-time energy use, identifying peak consumption periods, and implementing load-shifting strategies.

Lifecycle thinking is essential in project management for businesses striving to enhance sustainability. This approach considers the environmental and economic impacts of materials and products at every stage—from raw material extraction to manufacturing, usage and end-of-life disposal.

By understanding these stages, businesses can identify opportunities to reduce resource consumption, minimize waste and create more sustainable operations. Failing to adopt this perspective often leads to hidden costs and environmental consequences that undermine long-term goals.

Materials like metals, plastics and glass can be recycled efficiently if products are designed to facilitate the separation of these materials during disposal. Additionally, incorporating reusable elements—such as refillable containers or modular parts that can be upgraded rather than discarded—extends product lifespans and reduces demand for virgin materials.

Incorporating lifecycle thinking into other areas of your project management is critical as well. We’ll dive more into this later when we discuss how you manage your waste.

By identifying and tracking key performance indicators (KPIs), you can evaluate your company’s progress, pinpoint areas for improvement and demonstrate accountability to stakeholders.

for improvement and demonstrate accountability to stakeholders.

Commonly used KPIs include:

All of these provide quantifiable insights into the effectiveness of sustainability efforts. Together, these KPIs provide a comprehensive view of sustainability performance.

Monitoring and reporting these metrics also helps you maintain transparency and drive continuous improvement. Digital tools and software solutions can automate data collection and analysis, enabling real-time tracking of KPIs across multiple projects or facilities.

Dashboards that visualize progress against targets make it easier for teams to identify trends and adjust strategies accordingly. Regular sustainability reports should summarize these findings, detailing achievements, challenges and plans for future improvements.

Effective waste management is a critical component of any sustainability plan, particularly in industrial settings where waste often includes hazardous materials. Common types of industrial waste like solvents, heavy metals and chemical byproducts pose environmental challenges.

Improper disposal of these materials can lead to soil and water contamination, air pollution and long-term liability for businesses. Beyond the environmental impact, failing to manage waste responsibly undermines your sustainability efforts and can result in costly fines or damage to your company’s reputation.

To address these challenges, your waste management solutions play a significant role in meeting your environmental goals.

One effective example of sustainable waste management is solvent distillation, a process that allows businesses to recover and reuse solvents rather than disposing of them as hazardous waste. This practice not only reduces the environmental footprint of industrial operations but also saves costs by minimizing the need to purchase new materials.

This process separates the solvents from other substances through the application of heat. The basic principle is to heat a liquid mixture containing solvents, causing the solvent to vaporize. The vapor is then condensed back into a liquid form, resulting in the separation and recovery of the solvent.

Solvent distillation is a top environmentally-friendly and sustainable choice because when halogenated and non-halogenated solvents are distilled and ultimately recycled, economic resources are saved by reducing the purchasing of virgin raw materials. This process also reduces the generation of waste through a strategic solvent recovery plan and further prevents that waste from being generated in the form of pollution.

At Samex, our solvent recycling process minimizes the impact on the environment through the use of highly energy-efficient technology, which results in a high recovery volume. This closed solvent distillation process ultimately reduces volatile organic compound (VOC) emissions and enables the recycling and sustainable processing of chemicals.

Other sustainable waste strategies include recycling, where materials like metals and plastics are reclaimed, and waste-to-energy technologies that convert non-recyclable waste into usable energy.

Highlighting these solutions demonstrates your company’s expertise in providing eco-friendly waste management services while helping clients achieve their sustainability objectives.

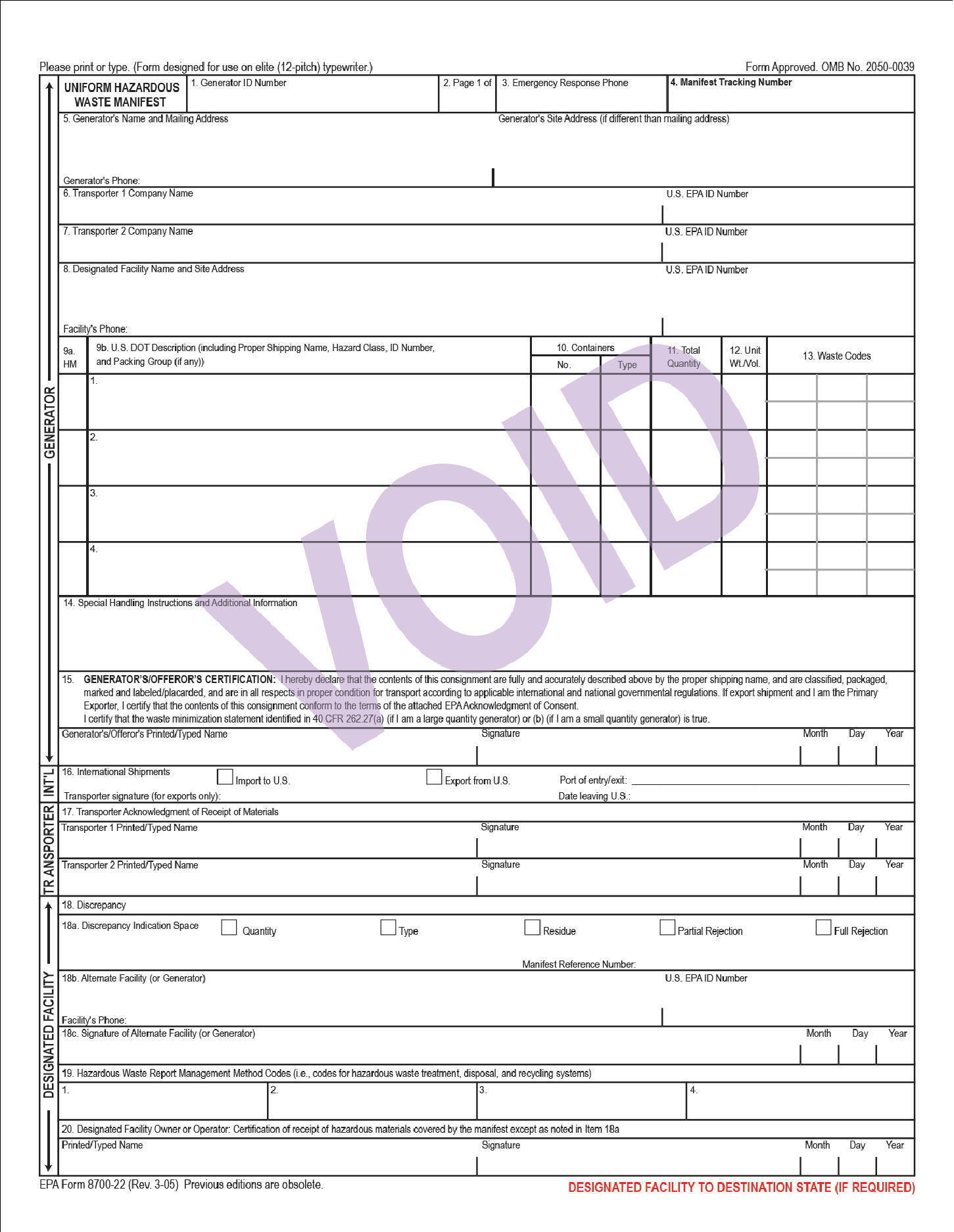

If your company generates hazardous waste and ships that waste to a facility in the United States, you’re no stranger to the biennial report—it rolls...

.png)

Flammable liquids are a common presence in both industrial and household settings, but their risks can be underestimated. If you do this, you’re...

.png)

Hazardous waste is often associated with pollution and regulatory headaches. However, there’s a silver lining.