How To Prevent Flammable Liquids Class B Fires

Dealing with flammable liquids requires more than just caution. It demands a proactive approach to safety.

4 min read

Larry Burton

:

Jul 9, 2024 9:45:00 AM

Larry Burton

:

Jul 9, 2024 9:45:00 AM

In industrial operations, a silent but significant risk looms large: flammable materials.

From manufacturing facilities to chemical plants, the presence of these materials requires vigilance that includes understanding their flammability class and ultimately how they are disposed of safely.

In this guide, we’ll dive into the National Fire Protection Association (NFPA) classifications, as well as the steps you can take to keep your employees safe and to minimize the impact of flammable waste on the community around you.

The NFPA classifies flammable liquids into three classes: I-A, I-B and I-C. The association, which has published the NFPA 30 with the most recent codes and standards, also classifies combustible liquids, which can catch fire, into three additional classes: II, III-A and III-B.

What is the difference between flammable liquids and combustible liquids?

Flammable liquids can easily ignite and burn rapidly at normal temperatures. They have a low flash point, which is the lowest temperature at which a liquid can produce enough vapor to form an ignitable mixture in the air.

Combustible liquids can catch fire, but they have a higher flash point compared to flammable liquids. They require higher temperatures to ignite, but once ignited, they can burn and sustain a fire.

Below are the NFPA classifications for flammable liquids, as well as the classifications for combustible materials:

Hazard classification for flammable liquids

|

Class |

Flash Point |

Boiling Point |

Examples |

|

I-A |

below 73°F (23°C) |

below 100°F (38°C) |

diethyl ether, pentane, ligroin, petroleum ether |

|

I-B |

below 73°F (23°C) |

at or above 100°F (38°C) |

acetone, benzene, cyclohexane, ethanol |

|

I-C |

73-100°F (24-38°C) |

---- |

p-xylene |

Hazard classification for combustible liquids

|

Class |

Flash Point |

Boiling Point |

Examples |

|

II |

101-140°F (39-60°C) |

---- |

diesel fuel, motor oil, kerosene, cleaning solvents |

|

III-A |

141-199°F (61-93°C) |

---- |

paints (oil base), linseed oil, mineral oil |

|

III-B |

200°F (93°C) or above |

---- |

paints (oil base), neatsfoot oil |

If your industrial facility generates flammable liquids, it’s important to know which class they fall in so you can mitigate the risk of fires. By knowing the flammability level of materials and substances, workers can handle them more cautiously and implement necessary fire prevention measures.

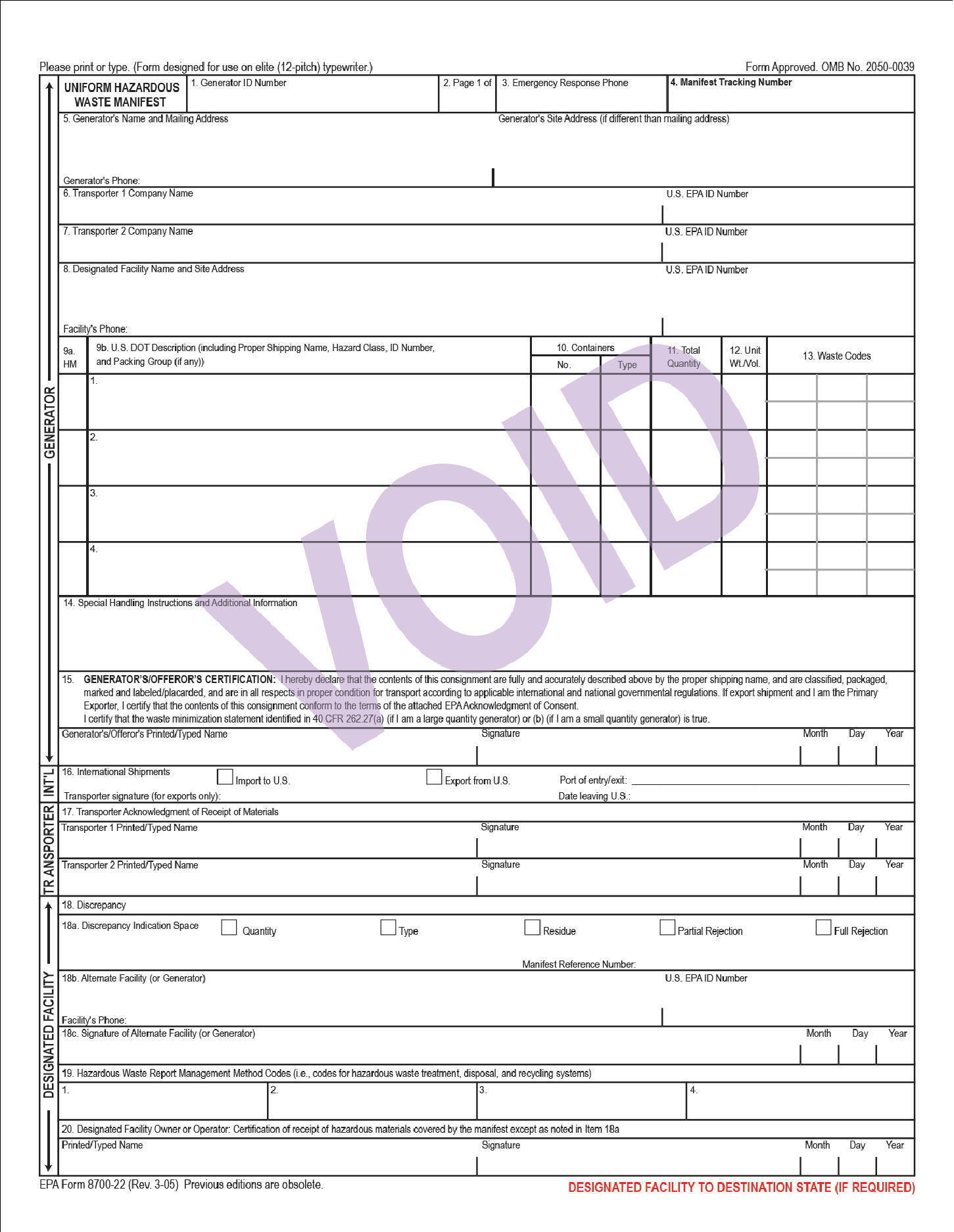

This risk assessment carries over from your facility to the transportation and disposal of flammable substances as well.

In the event of a fire, knowledge of flammability classes can inform emergency responders about the types of materials involved and the appropriate firefighting techniques to deploy. This knowledge enhances the effectiveness of firefighting efforts and reduces the likelihood of further escalation.

For example, flammable liquids with low flash points are highly volatile and can ignite at relatively low temperatures. Firefighters prioritize rapid cooling and vapor suppression to prevent ignition and control fires involving these liquids. Foam, dry chemical agents or specialized alcohol-resistant fire fighting foams may be used to smother the flames and suppress vapor formation.

Flammable liquids with higher flash points require different firefighting tactics. These liquids may produce less volatile vapors, but the fires can still spread rapidly and produce intense heat. Firefighters may use foam, water spray or dry chemical agents to cool the liquid surface, control the fire's spread, and prevent reignition.

Ensuring workplace safety is important in any facility, but when employees handle flammable liquids, safety becomes paramount. Here are six accident prevention tips that incorporate into your hazardous waste management plan:

paramount. Here are six accident prevention tips that incorporate into your hazardous waste management plan:

By implementing these accident prevention tips, businesses can create a safer work environment, reduce the likelihood of accidents and injuries.

Yet as a business that generates flammable liquid waste, there are steps you can take to ensure not only safety but also sustainability in the disposal process. Let’s explore how you can maximize the disposal of flammable waste while minimizing its environmental impact.

Where to send your flammable waste is an important decision. There are several methods solvent waste can be safely disposed of, from chemical recycling to landfill disposal. For businesses with sustainability objectives, solvent distillation offers an opportunity to meet these goals while safely disposing of flammable spent solvents.

How does solvent distillation work?

To achieve the highest level of sustainability, the disposal of your flammable spent solvents should end with nothing being wasted. For example, at Samex, any still bottoms that are generated during the solvent distillation process are transferred to our fuel blending area. In this area, still bottoms are blended with other flammable liquids to meet the specifications of the cement kiln, which will use the blend as an alternative fuel source.

Samex also has a water treatment plant where commercially clean nonhazardous water is repurposed to brick manufacturing. Solid byproducts from the treatment process are sent to the fuel blending area where they become part of the repurposed waste destined to the cement kiln to be used as an alternative fuel.

Opting for this sustainable solution for your flammable liquid waste fosters a healthier environment through conscientious waste disposal practices, while ensuring the disposal of your waste meets U.S. regulations.

.png)

Dealing with flammable liquids requires more than just caution. It demands a proactive approach to safety.

.png)

Hazardous waste is often associated with pollution and regulatory headaches. However, there’s a silver lining.

If your company generates hazardous waste and ships that waste to a facility in the United States, you’re no stranger to the biennial report—it rolls...